CU stud&Track Framing System MF200

TECHNICAL PARAMETERS

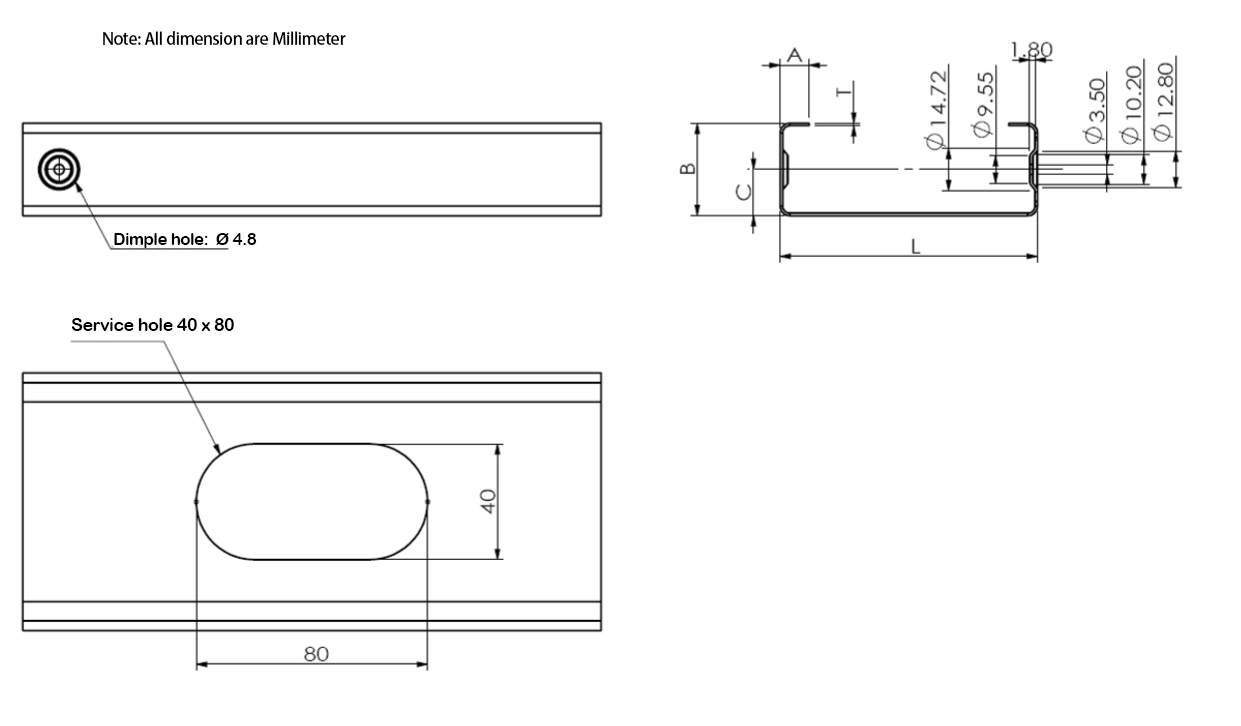

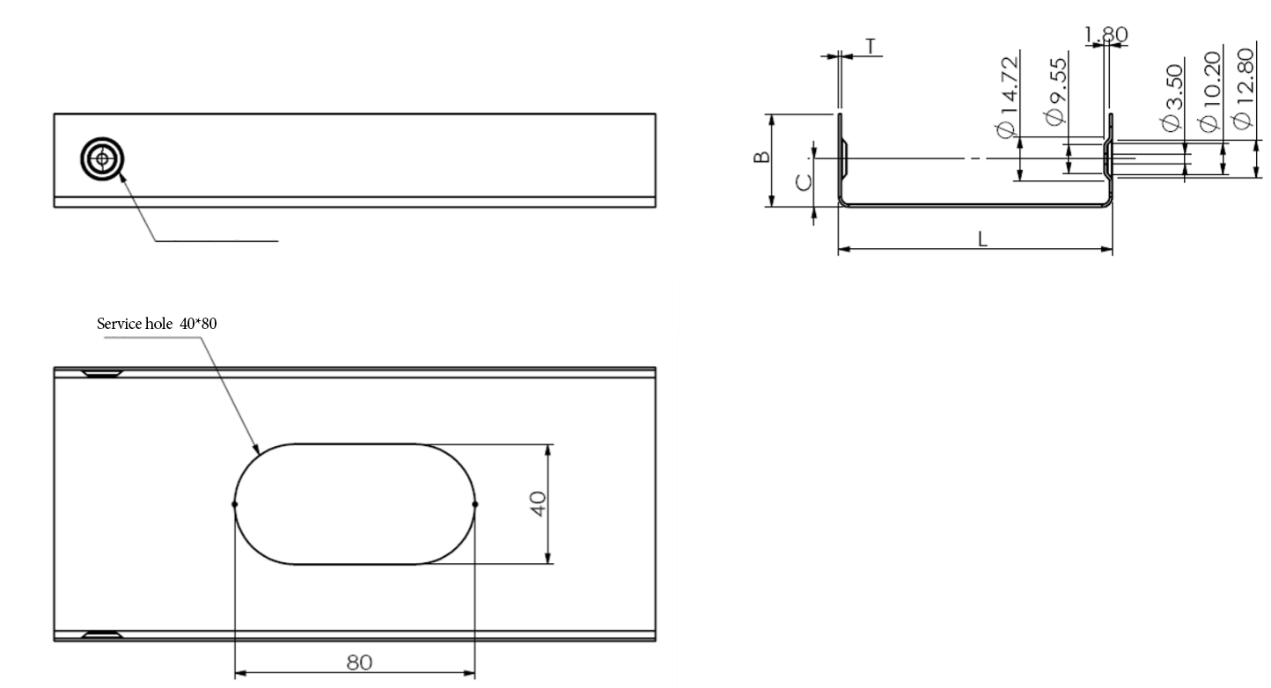

Ⅰ、Adjusted sizes:

Width: 75-220mm

Height: 32-51mm

(Lips: 8-15mm)

Coil thickness: 0.8-1.6mm

1.C profile

2.U profile

1)material : galvanized coil, aluminum-zinc coilSGC570 grade

yield strength : 550Mpa.

2)Tensile Strength: 355Mpa, 386Mpa,480Mpa

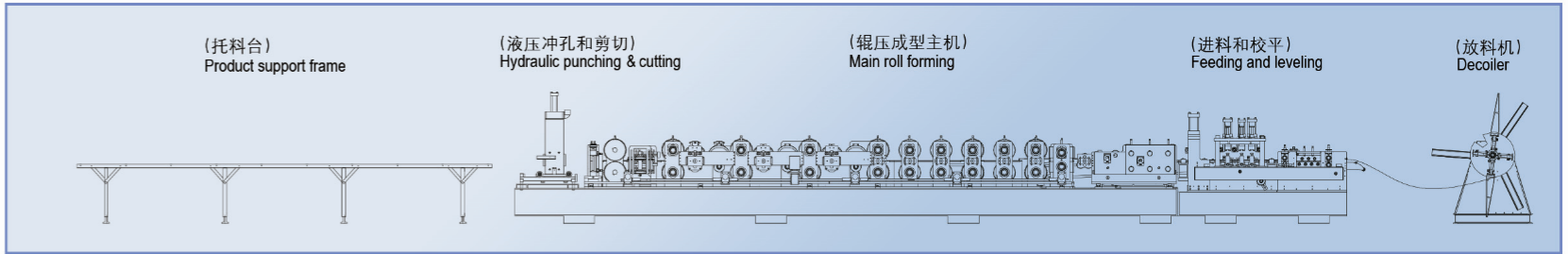

Ⅱ、Machine Components

- HydraulicDe-coiler ————————————————————- 1 set

- Leveling Device —————————————————————— 1 set

- Roll Forming System————————————————————- 1set

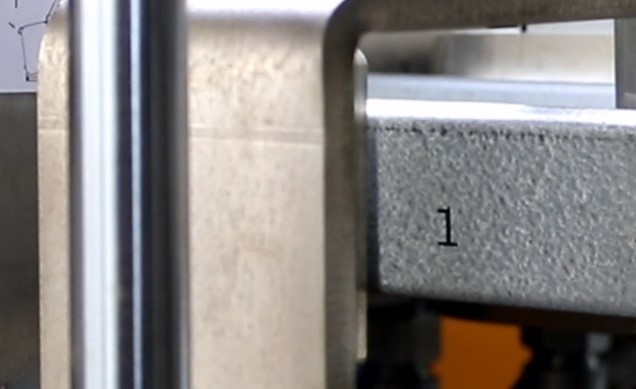

- Online Printer——————————————————————— 1 set

- Punching & Cutting Device ————————————————— 1 set

- PLC Control System————————————————————– 1 set

- Hydraulic Station—————————————————————– 1 set

- Run out table———————————————————————- 1 set

Ⅲ、Flow Chart

The flow chart is showing below.

Auto De-coiler→Leveling Device→Roll Forming System→Punching & Cutting Device →Run out table

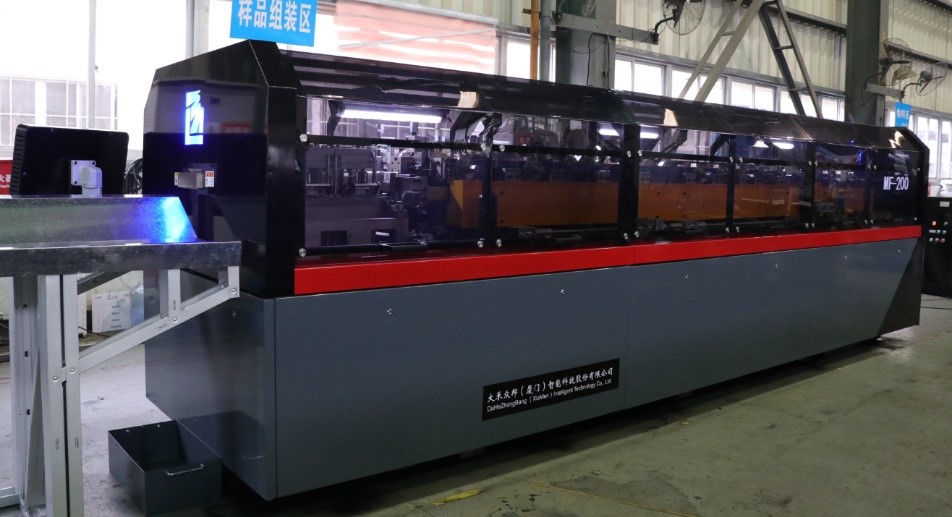

Ⅳ、Machine Picture

Ⅴ、Technology Parameters

The weight of theMachine:About 5.0T

The total dimension with un-coiler, run out table is:

(length)13m x (width)1.2m x (height)1.6m.

1)De–coiler

- De-coiler Type:Hydraulicauto de-coiler

- Weight capacity: Max 3.0T

2) Guiding: Guiding device is used to guide and fasten the raw material raw material into roll forming station steadily.

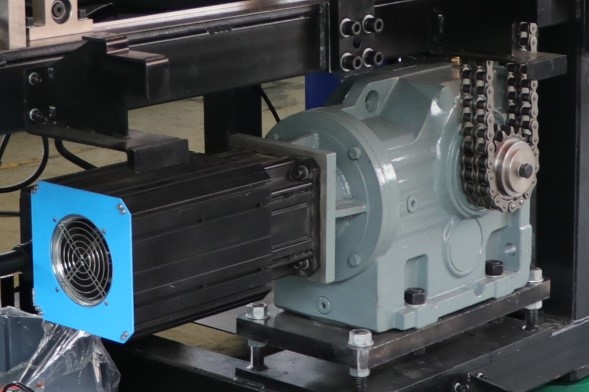

3) Rolling Forming System

- Ma

- Speed of forming: 35m/min

- Roller stands : 15rolling stands.

4) Shaft & Frame:

- Shafts of rollers are tooled by grinding machine for two times to ensure the precisionof final product.

5) Bearing: NTN brand from Japan.

6)Machine Frame

The frame of machine are designed as square tube shape and thickness of frame is 30mm in order to make sure the machine is capable to bear all accessories of this machine.

7) Flare control rollers

Flare device is made of two group rollers with manual adjusting device.

8)Changing sizes: Full-automatic (change sizes by PC control system)

- Machine is able to change purlin size within 1 minutes.

9)Hydraulic Punching

- All punching dies are made from Cr12. Driven by hydraulic station.Holes locations are able to set by PC panel.

10)Hydraulic cutting

- After punching, the cutter will shear the raw material automatically, driving raw material out of roll forming system.

- Shearing type: Hydraulic shearing with guillotine cutting.Cutting material: Cr12

11) Run out table

4 meter material receiving table, with a C stud & Track stacking platform.

12) Safety Guard:Safety Guard covers the whole machine to ensure worker’s.

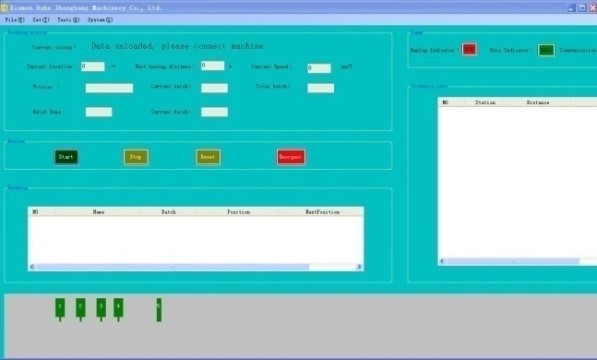

13) PC control system LG-R300.

- The control system MF 20 is able to program production CNCby inputingDahe’sTXT or CSV format and connect with machine directly. It can control machine auto-runningandrunning status dynamically, including punching, cutting and size changing.

15) PLC Control System & Components

- Control the quantity &punching length& cutting length automatically

- The Machine will be stopped while it is punching and cutting

- Automatic Length measures and quantity counting (precision +-0.5mm)

16) Profile image and application

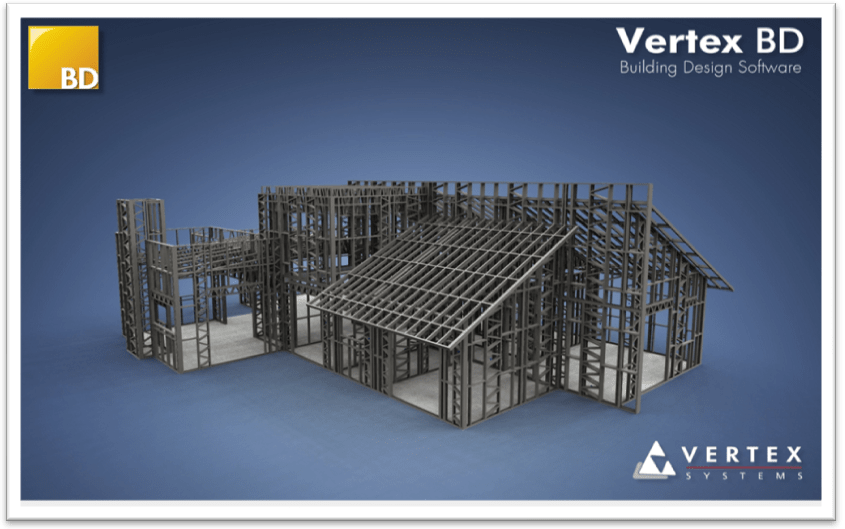

APPENDIX B: DEFINITION OF THE VERTEX SYSTEM SOFTWARE

Design Software Part – Vertex BD Pro

(International leading brand for LGS construction design)

The standard package contains:

1. Architectural Design

*Full architectural drawings

*3D browser with furniture&accessories

*Tools for creating presentable models ( e.g. Fascia, Soffits, Window& Do0r Trims, Guttering…)

2. 3D modelling and 2D Drafting

3. DWG, DXF,3DS,IGES and SAT- interfaces

4. Archiving tools

5. Open GL-rendering

6. Material database

7. Wall,floor and roof panels and roof trusses

* Automatic panel drawings

* Automatic truss structure drawings

* Automatic joist&rafter layout drawings

8. Bill of materials, cutting lists

9. First year support and maintenance